rms61moparman

Addicted to ArboristSite

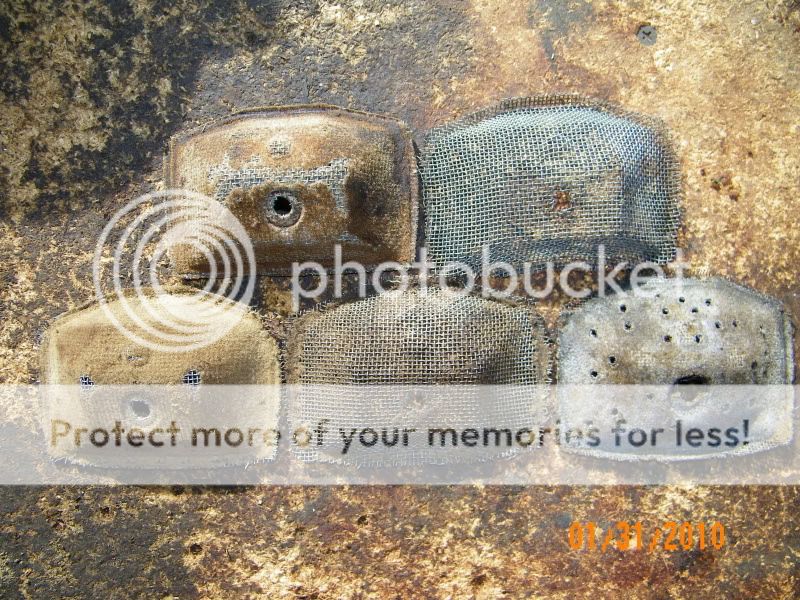

Your air filter can't be much worse than some of these beauties that were on some saws I acquired.

You would think folks would realize a filter is on there to serve a purpose, but evidently not.

And your right! There isn't a much more menacing sight, than a 3400 with a banana nose bar.

Gregg,

Filters like those are exactly why I have to smile when SOME on this site start making a big deal about "filtration"!!!LOL

They were among the worst air filters ever to begin with and then they lost their flocking and were even worse.

But it is AMAZING how many of them ran like that for years and are still going!!!

Yeah those aluminum bores with plated pistons were just plain JUNK!!!LOL

Mike