You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pioneer chainsaws

- Thread starter WesternSaw

- Start date

-

- Tags

- operator manual

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

RobShelton

ArboristSite Member

Missing spring?

Looks like you are missing the spring that locates the gear against the cover - away from the flywheel. It goes in the same slot as the decompression valve linkage. If that is gone, the gear may have been rubbing against the flywheel and wore it's self out. Rob

Looks like you are missing the spring that locates the gear against the cover - away from the flywheel. It goes in the same slot as the decompression valve linkage. If that is gone, the gear may have been rubbing against the flywheel and wore it's self out. Rob

pioneerman

ArboristSite Operative

Is your gear moving towards the flywheel when you pull on the cord? It should move in as the cord is pulled. Pull the gear off and check to see if the internal large threads are ok on the gear.

RobShelton

ArboristSite Member

Exactly as pioneerman says above, the gear should move toward the flywheel and the spring I mentioned pulls it back. It goes in the same slot in the gear the decompression lever rides in, but it has a "Finger" that sticks out to pull the gear back from the flywheel.

Hey Jerry, did you need to change the flywheel and ignition for the p40 starter to work? I would like to fix mine and I have some P40 parts laying around.

PB ;

I can`t remember exactly what I did on that saw but I will remove the starter cover tomorrow and reacquaint myself to what I did to make the parts interchange but I definitely did not change the flywheel or ignition. I really don`t remember which P series saw I used the parts from as I had several dozen of them ranging from P 38 to P41. I think it was a P 41 but can`t say for sure until tomorrow.

Pioneerguy600

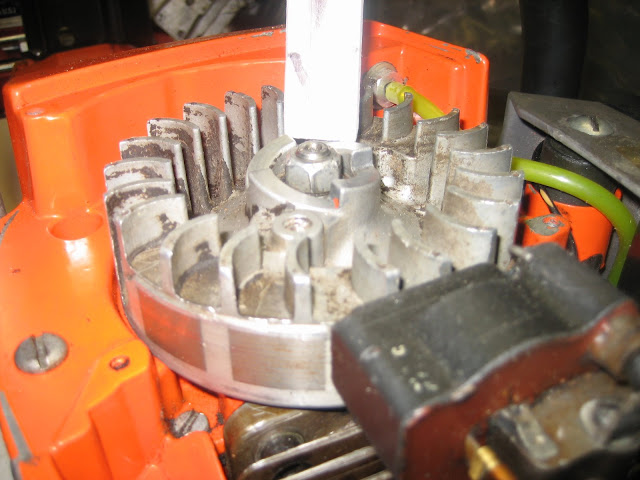

this is my starter .does it look worn to you ? It just seems strange that all of a sudden I get NO contact at all with the flywheel

Yes Rob Shelton is correct the spring that controls the decomp operator rod is broken and that would allow the engager to rub on the flywheel and that can cause the four points to be stripped off.. There is a splined part that rotates behind the engager when the rope is pulled that advances the black engager toward the flywheel, if it gets worn or stripped then the black part does not move forward far enough to reach the flywheel.

Pioneerguy600

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$225.16

OREGON 295397 Type C (All Round Yukon Chainsaw Protective Trouser, Black, Small

Express Shipping ⭐⭐⭐⭐⭐

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$19.99 ($3.33 / Count)

Firewood Log Splitter 45mm+32mm + 4 Handles (Square + Round + Hex Shank + Small Hex) Wood Log Splitter Easy Splitter Detachable Drill Bit Heavy Duty Electric Drills Screw Cone Driver Removable

JianShiMoQinDianZiShangWuYouXianGongSi

$56.99 ($0.38 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

mickeyd

ArboristSite Operative

CRAP !!! missing a spring ????? ...... No the gear is not moving out to engage with the flywheel. ...can someone post a picture of a working starter ? is the spring something specific to this starter or a generic hardware store spring ?????thanks you guys are great

Mike

Mike

CRAP !!! missing a spring ????? ...... No the gear is not moving out to engage with the flywheel. ...can someone post a picture of a working starter ? is the spring something specific to this starter or a generic hardware store spring ?????thanks you guys are great

Mike

I will pull one off a Farmsaw tomorrow and dismantle and take picts, its near 10 PM here now so just a little late for that sort of thing.

Pioneerguy600

HolmenTree

ArboristSite Guru

Good looking P45 ad.

RobShelton

ArboristSite Member

Farmsaw starter pics

I had to know if I was remembering it correctly, so here are a few pics. I also have the service bulletin from August 1982 showing how to use the Friction yoke (Spring) from a small P series saw in place of the original on the Farmsaw. And I quote, "Please be aware that the friction yoke, P/N 429572 from the small series saws can be installed in the FM housing and ensure completely satisfactory performance. Merely place the "leg" of the friction yoke in the gap provided in the lower side of the blower housing ribs (used when winding in the starter spring.) NOTE: Be sure the unit is equipped with a P/N 432520 pinion retaining washer used to limit the maximum travel on the bendix action." That washer (#432128) is under the screw that retains the pinion. The last pic is from the bulletin showing where the leg of the spring goes.

Looks like you will need the starter pinion gear #429892 and either the original friction yoke spring #432129 or one from the smaller series saws #429527. I'd want to use the earlier spring - seems to fit better and ought to be easier to find. You might need the pulley (#430609) if the twisted teeth on it are damaged. Check and see. I can probably get what you if needed, as I am going to get some stuff for mine! There is a local guy here who has parts. BTW, I am trying to purchase his inventory!

I had to know if I was remembering it correctly, so here are a few pics. I also have the service bulletin from August 1982 showing how to use the Friction yoke (Spring) from a small P series saw in place of the original on the Farmsaw. And I quote, "Please be aware that the friction yoke, P/N 429572 from the small series saws can be installed in the FM housing and ensure completely satisfactory performance. Merely place the "leg" of the friction yoke in the gap provided in the lower side of the blower housing ribs (used when winding in the starter spring.) NOTE: Be sure the unit is equipped with a P/N 432520 pinion retaining washer used to limit the maximum travel on the bendix action." That washer (#432128) is under the screw that retains the pinion. The last pic is from the bulletin showing where the leg of the spring goes.

Looks like you will need the starter pinion gear #429892 and either the original friction yoke spring #432129 or one from the smaller series saws #429527. I'd want to use the earlier spring - seems to fit better and ought to be easier to find. You might need the pulley (#430609) if the twisted teeth on it are damaged. Check and see. I can probably get what you if needed, as I am going to get some stuff for mine! There is a local guy here who has parts. BTW, I am trying to purchase his inventory!

CRAP !!! missing a spring ????? ...... No the gear is not moving out to engage with the flywheel. ...can someone post a picture of a working starter ? is the spring something specific to this starter or a generic hardware store spring ?????thanks you guys are great

Mike

Last edited:

WesternSaw

Addicted to ArboristSite

This Thread!

You Pioneer GURU GUYS on here in this thread really are fantastic with all the help you give us,the ones that are learning.Your simply the best.Holmen Tree nice add you posted on here.

Lawrence

You Pioneer GURU GUYS on here in this thread really are fantastic with all the help you give us,the ones that are learning.Your simply the best.Holmen Tree nice add you posted on here.

Lawrence

HolmenTree

ArboristSite Guru

Heres something for you Pioneer guys, The ad in the bottom corner,from 1984 but you never know they may still be around. Some interesting ANSI kickback discussion too..

Last edited:

RobShelton

ArboristSite Member

I googled the phone number (902)892-1234 and it seems to be a kindergarten.

I don't see a listing for a DB&J on PE Island. Oh well, thanks for the effort, HolmenTree.

I don't see a listing for a DB&J on PE Island. Oh well, thanks for the effort, HolmenTree.

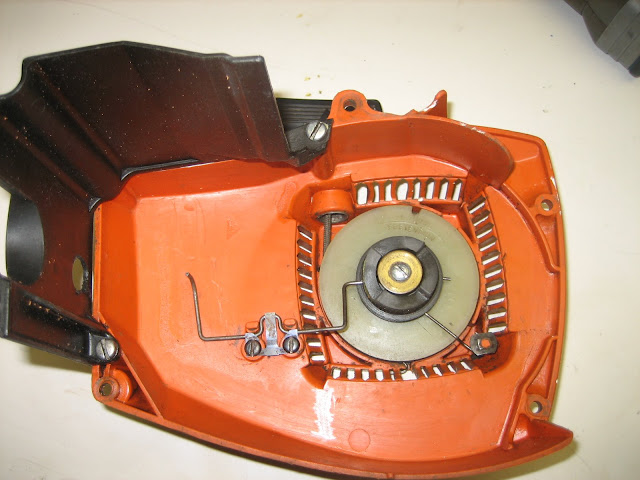

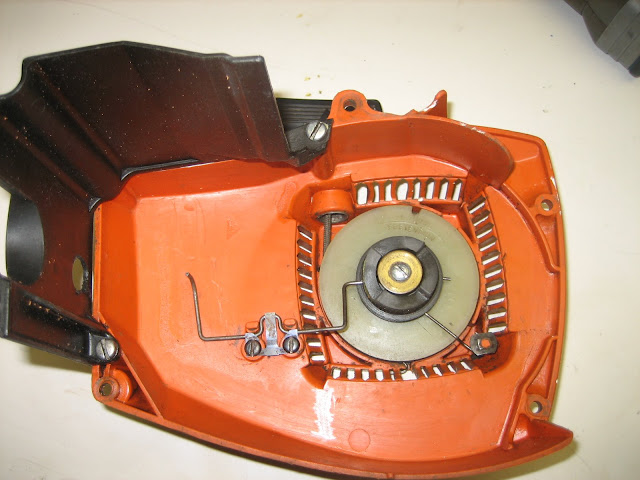

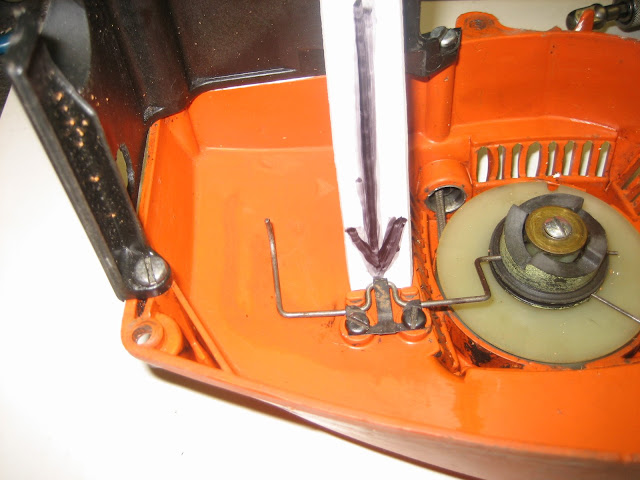

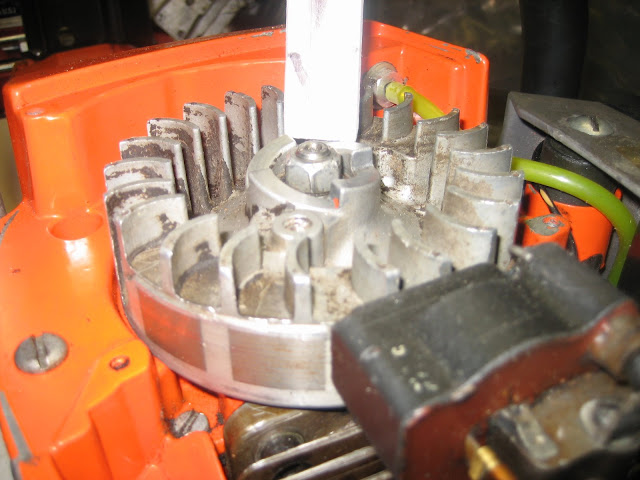

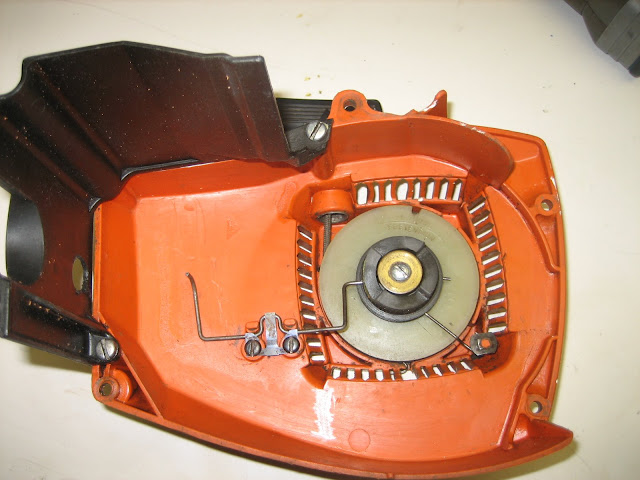

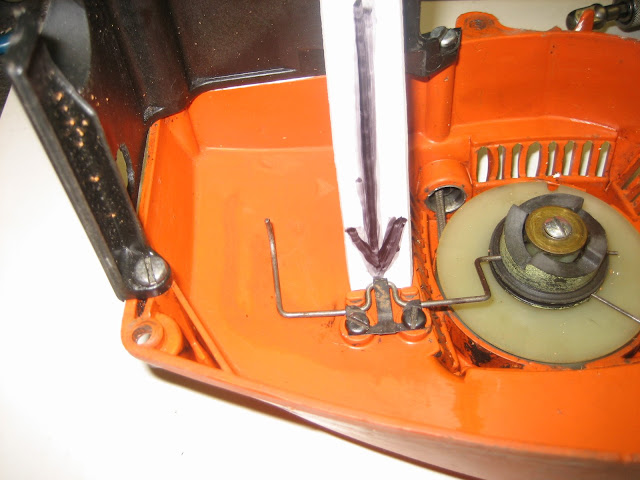

Ok here`s the picts of the starter and cover. The piece I used from a P series saw was the recoil spool that holds the rope, I call it a rotor. Now the engager which is black is moved in toward the flywheel when the rope is pulled and the rotor turns, its splined and it moves the black engager with the four points that mates to the four slots in the flywheel. Thus the rotating movement of the rotor is transferred to the flywheel affixed to the crankshaft.

Pict # 1 is of complete cover.

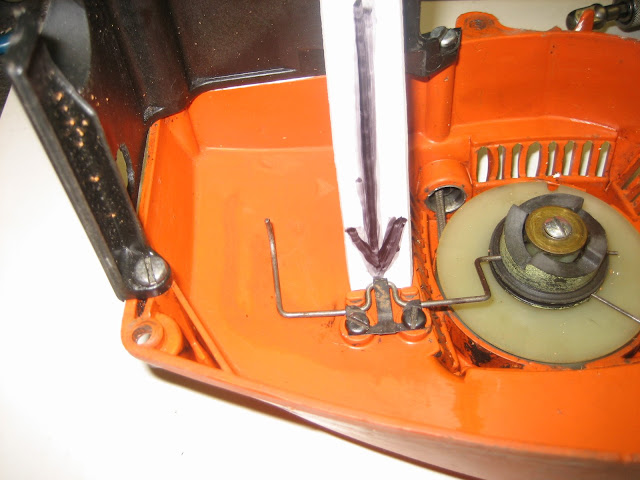

This pict is of the spring that holds the engager back away from the flywheel.

The black engager is splined to the rotor behind the engager.

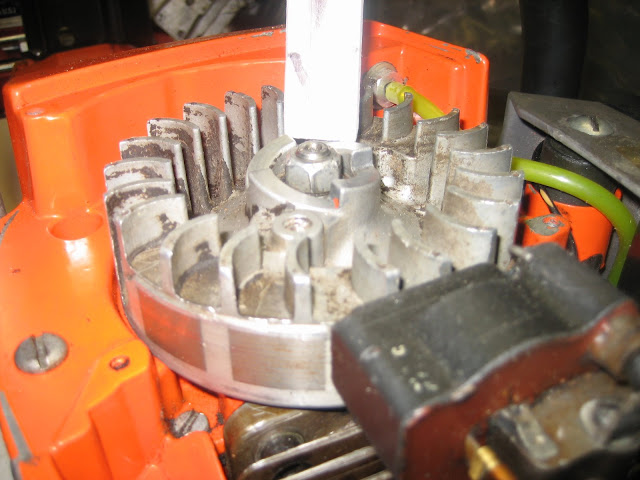

The engager removed reveals the rotor with the splines

.

.

The rest of the starter components

Finally the flywheel showing the part where the engager mates to it.

Pict # 1 is of complete cover.

This pict is of the spring that holds the engager back away from the flywheel.

The black engager is splined to the rotor behind the engager.

The engager removed reveals the rotor with the splines

The rest of the starter components

Finally the flywheel showing the part where the engager mates to it.

mickeyd

ArboristSite Operative

Ok here`s the picts of the starter and cover. The piece I used from a P series saw was the recoil spool that holds the rope, I call it a rotor. Now the engager which is black is moved in toward the flywheel when the rope is pulled and the rotor turns, its splined and it moves the black engager with the four points that mates to the four slots in the flywheel. Thus the rotating movement of the rotor is transferred to the flywheel affixed to the crankshaft.

Pict # 1 is of complete cover.

This pict is of the spring that holds the engager back away from the flywheel.

The black engager is splined to the rotor behind the engager.

The engager removed reveals the rotor with the splines

.

The rest of the starter components

Finally the flywheel showing the part where the engager mates to it.

WOW thats clean .Do you use that saw ?

EXCELLENT pics!!

Thanks

I can see that the retainer piece holding the return spring is broken AND the spring under the black spline is broken. how does the black spline/ gear come off?? I tried to turn it off and it is stuck .I dont want to break it more.

I was cutting wood today with a HUSKY 2100 what a monster, my aching back. I cant wait to get this pioneer running again

Mike

RobShelton

ArboristSite Member

Great photos Jerry!

Those pics really do a great job illustrating the starter system. I think we disagree on exactly what pulls the pinion gear/engager away from the flywheel. You second photo points to the spring that presses against the decompression lever. While I agree that spring is probably strong enough to push the gear back from the flywheel, I think it mostly locates the decompression lever. It probably does help push it back, but I believe the other spring that goes around the pinion/engager does most of the work. Why else would they have the other spring on the pinion?

Your photos also show the decompression lever riding on top of the pinion gear and leaving a distinct wear pattern, especially in the third pic. On the 2 Farmsaws I have had, the end of the decompression link was riding in the same grove on the pinion/engager as the other spring. And I didn't see any wear pattern as such. So I am betting the spring pointed to in picture 2 is pushing the lever against the pinion a bit too hard - the end of the link probably should be in the grove like the other spring. if it stays up there it will wear out prematurely.

Could I be wrong? Maybe. But I do feel strongly right. Course that never stops my wife from proving me wrong occasionally.

Hope I haven't touched off an argument: we are both trying to help out a fellow Pioneer saw nut!

Those pics really do a great job illustrating the starter system. I think we disagree on exactly what pulls the pinion gear/engager away from the flywheel. You second photo points to the spring that presses against the decompression lever. While I agree that spring is probably strong enough to push the gear back from the flywheel, I think it mostly locates the decompression lever. It probably does help push it back, but I believe the other spring that goes around the pinion/engager does most of the work. Why else would they have the other spring on the pinion?

Your photos also show the decompression lever riding on top of the pinion gear and leaving a distinct wear pattern, especially in the third pic. On the 2 Farmsaws I have had, the end of the decompression link was riding in the same grove on the pinion/engager as the other spring. And I didn't see any wear pattern as such. So I am betting the spring pointed to in picture 2 is pushing the lever against the pinion a bit too hard - the end of the link probably should be in the grove like the other spring. if it stays up there it will wear out prematurely.

Could I be wrong? Maybe. But I do feel strongly right. Course that never stops my wife from proving me wrong occasionally.

Hope I haven't touched off an argument: we are both trying to help out a fellow Pioneer saw nut!

ammoo74

ArboristSite Lurker

And I thought my Farmlite had a goofy set up. It is much simpler than the Farmsaw.

RobShelton

ArboristSite Member

Farmlite

I just looked at the IPL for a Farmlite and it looks like a more modern setup with pawls that disengage from centrifugal force after the saw starts up. Most of my other saws and power equipment looks more or less like that. The in-and-out motion and the decompression valve can be confusing on the Farmsaw, but it's really fairly simple once you see it in action.

I just looked at the IPL for a Farmlite and it looks like a more modern setup with pawls that disengage from centrifugal force after the saw starts up. Most of my other saws and power equipment looks more or less like that. The in-and-out motion and the decompression valve can be confusing on the Farmsaw, but it's really fairly simple once you see it in action.

Those pics really do a great job illustrating the starter system. I think we disagree on exactly what pulls the pinion gear/engager away from the flywheel. You second photo points to the spring that presses against the decompression lever. While I agree that spring is probably strong enough to push the gear back from the flywheel, I think it mostly locates the decompression lever. It probably does help push it back, but I believe the other spring that goes around the pinion/engager does most of the work. Why else would they have the other spring on the pinion?

Your photos also show the decompression lever riding on top of the pinion gear and leaving a distinct wear pattern, especially in the third pic. On the 2 Farmsaws I have had, the end of the decompression link was riding in the same grove on the pinion/engager as the other spring. And I didn't see any wear pattern as such. So I am betting the spring pointed to in picture 2 is pushing the lever against the pinion a bit too hard - the end of the link probably should be in the grove like the other spring. if it stays up there it will wear out prematurely.

Could I be wrong? Maybe. But I do feel strongly right. Course that never stops my wife from proving me wrong occasionally.

Hope I haven't touched off an argument: we are both trying to help out a fellow Pioneer saw nut!

Hi Rob;

The piece of wire that wraps around the engager actually is not a spring at all, it holds the engager just enough to cause the engager to slip up the spiraled spline of rotor. If you remove it the engager just turns with the rotor, it will not slip up the spiraled spline of the rotor. That wire slips up and down the post its attached to on the cover to allow the engager to move, it has no return ability at all. The position of the decomp actuator on the engager does not matter much at all, the little spring steel clip does not have enough pressure to hurt the material the engager is made from, by letting it ride in the position its in is like adding a slight bit of extra tension to return the engager back down the spline of the rotor. To see how each piece works just remove one piece at a time and then pull the cord, without the wire piece that wraps around the engager it will only rotate with the rotor and not rise up the spiraled spline.

Pioneerguy600

Similar threads

- Locked

- Replies

- 36

- Views

- 6K

- Replies

- 15

- Views

- 2K

- Replies

- 10

- Views

- 5K